How It Works by Dr. Dyno, American Iron Magazine, September 2010

EFI TUNERS

What’s available and what they do

I’VE WORKED WITH ENGINES FOR MANY YEARS, so the importance of maintaining a proper air/fuel ratio (AFR) is second nature to me. It just never occurred to me that other riders might not understand why it’s so important. Then, in a campground at Sturgis not too long ago, a Harley owner asked me, “What’s all this about air/fuel ratios, and does it really matter?” I started thinking about all the answers an engineer would give, but they would just overwhelm him. Instead, I said, “You control the volume of air going into your bike’s engine by how much you twist the throttle. Then the carburetor or fuel injection controls how much fuel is delivered to give the engine the right air-to-fuel ratios. If everything is working correctly, the ratios change as you dial up the power, giving you an enjoyable ride. If the ratio is not correct, the bike may be sluggish, unresponsive, run hot, or run fine, but get lousy gas mileage.” That he understood.

|

COMMON EFI QUESTIONS

Another question I often get is, “Would you rather tune a carbureted or fuel-injected Harley?” Carburetors are pretty simple. I run an idle, cruise, and full-throttle test on the dyno and simply adjust the idle screw, needle or midrange jet, and main jet to get the respective air/fuel ratios I want. I’m shooting for a 14:1 AFR at cruise and a richer 13:1 AFR at full throttle, tuned on the leanest running cylinder. To reduce deceleration popping, I may have to set the idle mixture a littler richer than the 13-14:1 I’d prefer. Bikes with performance cams or an open exhaust system often need the additional step of tuning the exhaust to fix a low-to-midrange rich area to improve torque output and fuel mileage. Tuning a carb is a pretty straightforward process, but it’s often dirty work and I prefer not to cover my hands with gasoline.

By comparison, tuning fuel-injected Harleys with any of the products we’re looking at this month is nice, clean work. Even so, sometimes it’s just plain hard and even frustrating work mentally. Hard because I get some bikes with tuning products that are too basic to do the job as well as I’d like, so it’s all about compromises. It’s frustrating when I have to use a tuner that’s as slow as dial-up Internet, knowing all the while there’s another one available that’s the equivalent of a highspeed server. This is all because whereas a carburetor is in effect its own airflow meter, the type of fuel injection H-D uses doesn’t have a direct measure of the changes in airflow as the rider adjusts the throttle. Instead, its electronics rely on look-up tables of throttle position, manifold pressure, and rpm readings to determine how long to open (pulse) the fuel injectors. The collection of these fuel tables, one for each cylinder, and the corresponding ignition advance tables are referred to as maps. When component changes affect the airflow in ways the sensors can’t measure, we get mixture errors, resulting in loss of power or mileage. Worse, all it takes to cause a real mess is some let-me-try-this “expert” with one of the ECM programmers loading bad numbers into a few map cells.

In 2007, H-D put O2 sensors on all models, which has people wondering, “Aren’t they supposed to automatically tune around or compensate for any AFR issues?” In a word, no! The full explanation is in the July issue, but the short answer is that they were put on to operate the engine at 14.7:1 AFR (you may see 14.6), which is the stoichiometric ratio for gasoline that produces the least emissions. The sensors will adjust for an air cleaner and/or exhaust system change and bring the AFR back to 14.7:1. Truth is, the O2 sensors are in effect a set of blinders. Once they get locked into closed loop (also explained in July), they override even perfectly tuned maps and totally ignore altitude and temperature sensors, as well as how hot the oil or the rider gets.

You may hear some tuners talk about volumetric efficiency (VE). They may even claim to tune by VE, saying it’s somehow superior to the “old” AFR tuning. Turns out, you don’t have to know anything about VE to properly tune a bike. VE is not nearly as complicated as it may seem. VE is the actual airflow through an engine expressed as a percentage (efficiency) of the flow computed from the engine’s displacement (volume). By displacement, we are referring to its size, like 95". Sometimes the word metric is added to make it sound more impressive, I guess. In actual H-D engines, VE can vary from nearly 50 percent to over 100 percent, depending on rpm, cam profiles, and exhaust system efficiency. Using one of the ECM programmers brings up the VE tables. Adjusting their percentages doesn’t change the actual airflow through the engine or its VE, but it does cause the ECM to add or remove fuel. It’s similar to changing the engine displacement or injector size numbers to fool the ECM into changing fuel delivery when the overall maps are too rich or lean. So, whether done indirectly with VE tables or directly by percentage of fuel as with a Power Commander, the result is the same: the tuner gets to dial in the air/fuel ratios he wants. A side benefit of VE tuning is the resulting table gives a good indication of how the exhaust system is working with the cams. Good tuners can use that info to their advantage and tune the pipes for more low and midrange torque, but that requires retuning VE again. And, in my opinion, really good tuners don’t need VE tables to properly tune exhaust systems.

TYPES OF TUNERS

Speaking of fooling the ECM, isn’t that what the add-on tuners do? Some yes, most no. Let’s talk about stacking first, since it’s closely related. Stacking means adding more than one tuning product, either because some salesman says you need his or you think you’ll get more power that way. For instance, someone adds a Power Commander to a bike that already has a Screamin’ Eagle Race Tuner on it. Well, first of all the SERT isn’t “on” the bike. Like the other ECM tuners, it’s really just an electronic key that allows you to change the stock ECM’s internal maps either by tuning the tables as I just described or simply downloading canned maps. All it does is replace the stock set of numbers with another set. If the maps in the ECM don’t work out correctly air/fuel wise, adding a Power Commander is often a good way to adjust them in a reasonable amount of dyno tuning time. So the Power Commander isn’t really stacked on the SERT. However, all the engine wants is the right amount of fuel.

|

The Power Commander (PC) is also a good example of fooling the ECM — if we go back to the PC II of 10 years ago. It used sensor offset technology by intercepting ECM inputs, such as the 0-to-5-volt throttle position sensor signal, and modifying it before letting the ECM see it. Decreasing the voltage makes the ECM lean the mixture. But if more fuel is needed at full throttle, sending the ECM more than 5 volts doesn’t work, so you have to fool the ECM at some other input. Was it air temperature or atmospheric pressure we used? Can’t remember, but I still have one customer with a II whose Harley runs so well, he sends all his friends to me, but he won’t let me upgrade his bike to a newer Commander like a IIIr or the current III USB and V models. They let the ECM do its thing without interference, and then, at its output, adjust the pulse lengths driving the injectors and the timing pulses to the ignition coils.

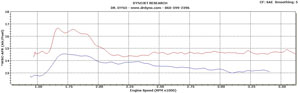

Let’s take a look at the air/fuel curves of a customer of mine: Terry and his 2008 Ultra Classic SE 110". The graph is the before (red) and after (blue) AFR curve of the rear cylinder during my 25 hp cruise test. The bike had over 90 hp and 110 ft-lbs. of torque, but had major problems getting off the line with a Devil’s Tower of a lean spot at quarter throttle roll-on. If you digested my July article, you’ll recognize this is a closed-loop system as evidenced by the hunting for 14.7:1 in the idle area to the left and the cruise area to the right. But when the loop opens for acceleration and fuel delivery goes back onto its maps, those maps need to be right. Many tuners, including the one who used a SERT on this bike, apparently don’t understand this and concentrate instead on tuning the other open loop area, the upper three-quarters of throttle and rpm (top end). And if his dyno only had one channel of air/fuel reading the front cylinder, he wouldn’t have seen the problem even if he did run a proper inertia- only cruise test. Without a lot of clutch slipping, a bike will fall on its face in such a lean spot. And if you’re leaned over in a turn like Terry and his lady were on a back road, it will fall on its side. Not a pretty sight, but, fortunately, nobody was hurt. The same can’t be said for the $30,000 bike. So, what product could be used to fix this and, more importantly, guarantee it’s fixed to a concerned couple who never want a repeat performance? “Here, try this,” isn’t an option! Obviously, we need a tuner with a 250-rpm resolution to correct the problem without causing unwanted side effects. A scan down our chart (below) lands on the Power Commanders. But what about the ECM programmers, in this case the SERT already used on the bike? It has an acceleration enrichment table that might have been just the ticket. Terry already owned it, and it was locked to his ECM, but he didn’t have a copy of the modified maps the tuner loaded into the bike. Without them, I’d have to start over and redo any good tuning done previously. I didn’t want to spend the hours it would have taken to do the perfect tune Terry was looking for, and he certainly didn’t want to pay me to tune with something that wasn’t working for him. Besides, I wanted to take the bike off the O2 sensors so I could tune all areas for smoother and cooler running. I used a Power Commander III USB and tuned it to the blue line eliminating the stumble and making it much more responsive. For the best of both worlds, Terry can go back to emissions-legal closed-loop anytime he wants simply by reconnecting the O2 sensors. The stumble will still be eliminated because that’s in the open-loop area. As for peak horsepower and torque, we picked up just one each, which didn’t matter to Terry.

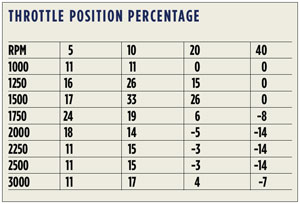

Could one of the auto-tuners currently on the market have found and fixed the lean spot? Yes, some would have, but it wouldn’t necessarily be plug-and-play installation. Others, like those based on narrowband or the stock O2 sensors, wouldn’t get my vote since, in my opinion, basically what they do is “upgrade” bikes to the same closed-loop from 2007. And, again in my opinion, they all need to be tuned. The wideband, sensor-based auto-tuners would get the job done but aren’t set-it-and-forget-it because their tuning range is purposely limited. Let’s use the auto-tune add-on module for the Power Commander V as an example. We’ll use a section of the actual Throttle Position fuel table (above) I developed while tuning the stumble out of Terry’s bike. It’s a PC III table, but the numbers would’ve been the same had I used a PC V (with the addition of a 15 percent column). The number in each cell is the percent of fuel I added or subtracted to adjust the AFR. As you might expect, I had to add a lot of fuel to eliminate the lean area.

The wideband auto-tuners are map-based, so let’s say the PC V started with an all-zero table, as I did on the dyno. The PC V has two more tables for use when connected to the autotune module. One is the target AFR table, which is a list of the desired final AFR values. It’s equivalent to the mental one I use when tuning on the dyno. The other table looks just like the fuel table but is called a trim table. As the bike is run this table fills in with the offset values the fuel table needs to achieve the target AFRs. It does all this quickly for any cell the bike is operated in, but, unlike me, it’s limited to numbers between +20 percent and –20 percent. This is to prevent anything “crazy” from happening. So whether the bike was operated on the street or on a dyno, it would develop the same numbers I did except that the 24, 26, and 33 would max out at 20. All this happens magically inside the PC V, but now it needs human intervention for two reasons. Although the trim table values are applied to the fuel table values, they don’t permanently change the fuel table or take effect until the bike warms up for one minute and hits 160 degrees F. We need to check the trim table for numbers in each cell and any 20s. A zero in a cell means either the AFR was good there or, more likely, the engine wasn’t operated in that cell. It’s very common to see zeros in high rpm and throttle opening cells for streettuned bikes because of the safety issues associated with running the bike at those extremes. Dyno tuning is the way to do it safely. Now we need to click on the “accept all trims” button to permanently offset the numbers in the fuel tables and reset the trim table to all zeros. I’ve had bikes with auto-tuners that ran terrible until they warmed up, simply because no one ever accepted the trims. To complete the tune, any cells that had maxed out at 20 need to be rerun and the new trims accepted. Once the trim tables stop developing numbers larger than 1 or 2, the tune is complete and the auto-tuner should be removed or turned off to prevent it from tuning around a developing problem such as a sensor going bad.

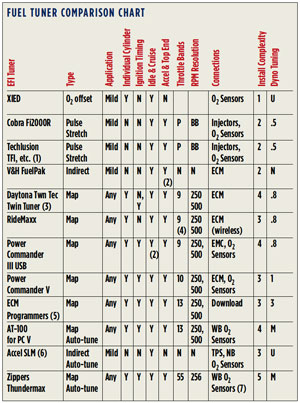

INDEX FOR EFI TUNER COMPARISON CHART

Types Of EFI Tuners

O2 Offset: These are voltage dividers that connect in series with the factory sensors and richen the mixture. Pulse Stretch: This is when the injectors are held open for an additional proportional (P) time to increase fuel delivery.

Indirect: Intercepts and modifies inputs to the ECM, like the manifold pressure or throttle position (TPS) sensors, to affect the ECM’s outputs.

Map: Uses tables of rpm and throttle position or manifold pressure to directly set or offset injector pulse width and ignition advance in each table location or cell.

Auto-tune: Uses feedback from O2 sensors in the exhaust system to automatically adjust the AFR. Map-style tuners use target AFR tables.Application

Mild: Best for applications without performance cam changes. These tuners run out of adjustment range or resolution for the rapid AFR changes and front/rear cylinder differences that high-performance cams typically cause.

Any: Mild to wild, these tuners, all map style, can be used to compensate for almost any extreme of AFR requirements.

Individual Cylinder: Does the tuner allow independent adjustment of each cylinder?

Ignition: All the tuners adjust fuel, but do they also allow specific adjustment of ignition timing?

Idle and Cruise: With closed-loop systems, does the tuner allow tuning in the closed-loop areas? A Y has emission regulation implications. Some require additional purchase of O2 sensor eliminators.

Acceleration & Top End: With closed-loop systems, does the tuner allow tuning in the open-loop areas? Open loop is accelerator “pump” (especially off-idle) and above three-quarter throttle or three-quarter maximum rpm.

Throttle Bands: For map-style tuners, the number of different percentages of throttle opening columns from 0 to 100 percent in the fuel and ignition tables. Lower number of bands reduces dyno tuning time. N = is for indirect tuners, rpm resolution is not user identifiable.

RPM Resolution: The width of separately tunable rpm bands. BB is what I call broad brush. For instance, the Fi2000 has one-rpm breakpoint creating two-rpm bands; the Techlusion two breakpoints, three bands. N means indirect tuners; rpm resolution is not user identifiable. The designation 250, 500 means user selectable rpm bands, while 250/500 means 500-rpm bands above 3000 rpm. Using the widest effective band reduces dyno tuning time.

Connections: Where the tuner connects into the system.

Installation Complexity (1-5): This includes the time for an owner to install the unit on his bike, to set in a base tune, and, in the case of the auto-tuners, to make adjustments later. Requiring the use of a computer adds one point.

Dyno Tuning: The effectiveness on any of these products can be checked on a dyno using idle, cruise, full throttle, and decel pop tests. A number in this column is an estimate in hours of the time it takes a skilled operator to perform a tune of both cylinders over the full range of rpm and throttle openings on a dyno equipped with dual AFR sensors. A U means the device is unadjustable. An N means the manufacturer does not provide the information needed to effectively adjust the product on a dyno. An M means a dyno is the safest way to tune maximum throttle openings and rpm. ■

CONCLUSION

When deciding on a tuning product, remember your bike isn’t impressed by the trick names the ad departments come up with, or the salesmen’s promises, or even Dr. Dyno. It just wants the right amount of fuel added to the amount of air you give it when you twist the throttle. AIM